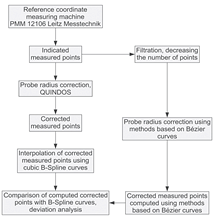

Optimisation methods for programming CNC machine tools

Wit Grzesik

![Recognition of geometrical features of the workpiece (mold base) in NX CAM program [6]](/foto/aktualnosci_lista2/2/ikona_eng_0013.png)

Recognition of geometrical features of the workpiece (mold base) in NX CAM program [6]

This paper presents some important methods of optimisation of CNC programming which covers algorithms of feed changes along the path of tool movement, the concept of feature-based recognition machining (FBM), numerical simulation (FEM/FEA), advanced virtual modelling of machining systems, real-time process simulations with the use of digital twins (DTs) and intelligent control strategies based on the STEP-NC standards. Selected examples of practical industrial applications are overviewed and future development trends are discussed.

KEYWORDS: CNC machine tool, control program, feed optimization, numerical simulation, virtual simulation, STEP-NC interface

![An example of a closed-loop self-learning STEP-NC machining system [2, 10]](/foto/aktualnosci_lista2/./ikona_eng_0012.png)

![The result of chip formation simulation using SPH method for the workpiece and FEM for the tool: a) 3D view and b) contours of effective plastic strain in the cutting zone [10]](/foto/aktualnosci_lista2/./ikona_eng_0011.png)

![Smart machining system architecture [3]](/foto/aktualnosci_lista2/2/ikona_eng_0010.png)